WHAT WE LEARNED FROM OUR LEED FOR HOMES CHARRETTE

We have completed our LEED charrette for our single-family home that we are designing in Michigan. Thanks to Rich Bloem and Alex Goosen from True North Homes (general contractor) for their assistance in putting the charrette together and facilitating the day.

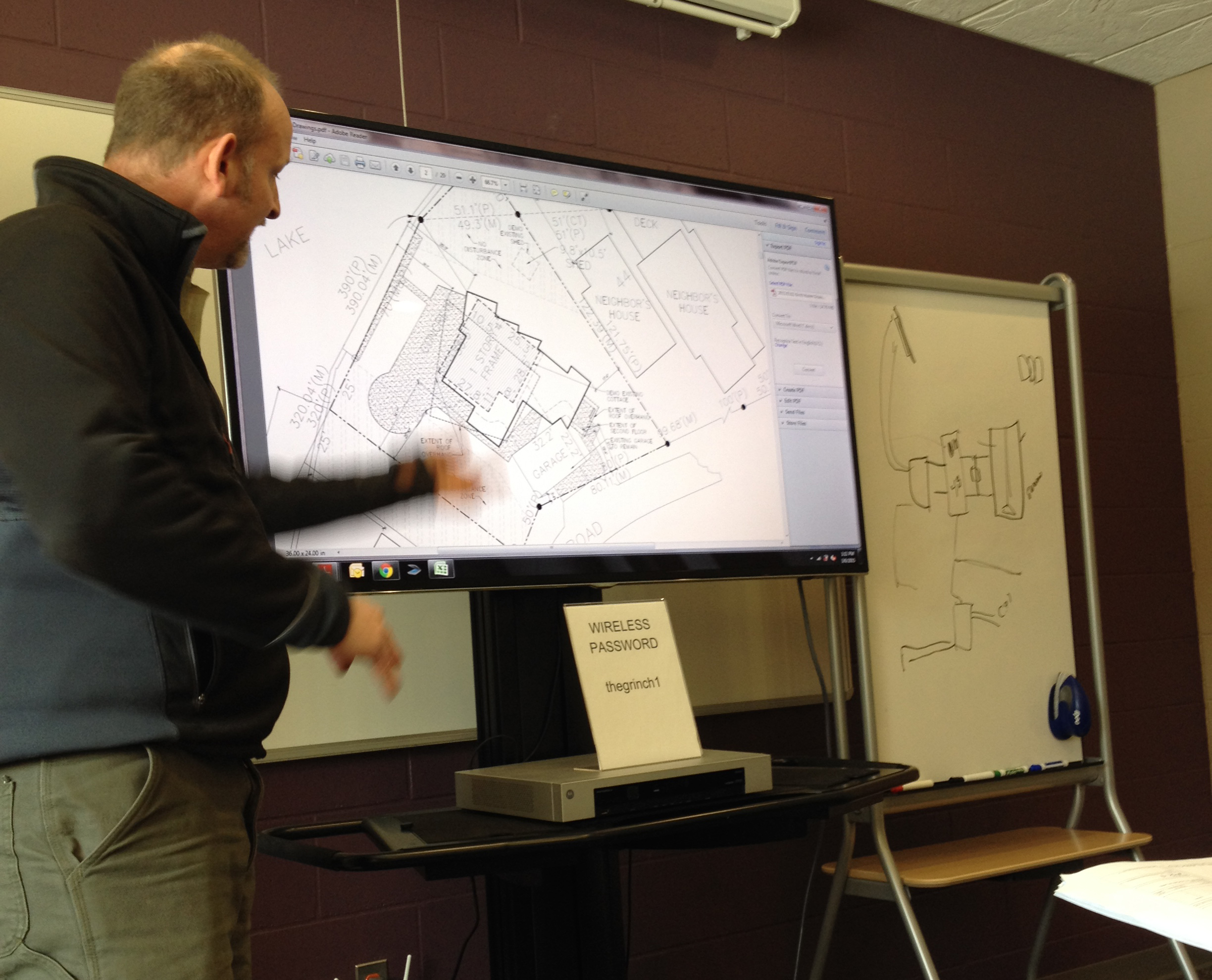

The first thing one needs to do for a successful charrette is manage the logistics. We met at a great venue called the Pinnacle Center in Hudsonville, Michigan and we were treated with a great conference room full of all the necessary AV equipment that we needed, as well as coffee, breakfast, lunch and breaks throughout the day to make the whole thing very enjoyable. Don’t overlook the details and making the participants comfortable during the charrette process.

There were about 20 people who participated in the charrette. Most were there all day. Some came and went. The general contractor, the architect, the landscape architect and many of the subcontractors and material suppliers contributed to the successful day. We discussed all the features of the home and all the systems necessary to construct it in an open forum where everyone contributed. Some had experience in doing green homes and for others this is their first exposure to the process. Several of the participants have been working on preliminary LEED for Homes checklists for the project prior to coming to the charrette. For this particular home, because of its size, we need to achieve 100 credits in the rating system to obtain our goal of platinum certification. Our preliminary checklists were reflecting scores between 88 and 94 credits. The variation was coming mostly from the HERS score which was anticipated to be anywhere between HERS index of 30 and a HERS index of 44.

Alex Goosen managed the HERS preliminary rating process, and Jamison Lenz was our LEED Provider from the Green Home Institute, Grand Rapids, Michigan.

As a team we went through the entire LEED checklist and looked for synergies between various systems and other design and construction strategies to improve the home’s design to a point where we could receive platinum certification. The design itself had already taken into account many passive design elements to make the process easier. The home was already set up with south facing roof to accept PV and/or solar thermal systems to improve the homes energy performance.

One of the most interesting discussions of the day was about the homes heating and cooling systems. It was determined that there are more heating load than cooling load, but that it was important that both heating and cooling be provided. The initial basis for the design was a forced air system for both heating and cooling using highly efficient equipment. And there was a need to make the home more energy-efficient to get it from the gold to the platinum level of certification. Doug Stull, Bel‐Aire Heating & Cooling was in attendance and provided great input, and practical analysis, as well as Greg Mulder, a specialist in renewable energy systems (such as PV, solar thermal and geothermal systems) provided his perspective as well.

After a great deal of discussion and various systems options, we decided to proceed in evaluating a radiant hydronic floor heating system for the first floor, supplemented with a forced air heating system for the second floor that would also serve as the forced air cooling system for the entire house. We decided to supplement both systems with solar thermal roof mounted water heating to preheat the water needed for the hydronic floor system and PV solar electric panels supplement the entire system including the forced air system cooling and heating. The PV solar system was in the range of 5 KW to 10 KW. Solar thermal provides support to a natural gas fired boiler that helps maintain the water temperature under any conditions. Successfully integrating the systems together improves our HERS score. Also we integrated the domestic hot water heating with the radiant floor heating by having those two system share their heat energy which is an important link to save energy. This is just one of the many meaningful and wonderful discussions that took place during the charrette.

A few lessons learned:

- Michigan has true net metering (you may know that Florida does not, shame on the sunshine state)

- There are many options and heating and cooling systems in Northern climates.

- Forced air heating and cooling is most likely the least expensive first cost solution.

- Hydronic radiant floor systems provide an incredibly comfortable way to heat a home.

- The return on investment calculations that the subcontractor will provide will help us make a decision between first cost and life cycle cost for the system that we end up selecting.

Landscape: We learned there were many credits available in the landscape categories. This includes water conservation in the irrigation system and native plantings and native low impact design solutions. Since we are working on an existing site we may choose to remove some of the existing impervious surfaces and replace them with landscaping and/or pervious surfaces. The landscaping and irrigation credits will be important to us if we are to achieve our certification goals. Mike Bruggink, Fen View Design, is the Landscape Architect.

SIPs (structural insulated panels): We learned that LEED encourages and rewards the use of sip panel construction in the LEED for homes standards. SIPs should help us obtain a very good HERS rating, create a well-insulated and tightly constructed building envelope, speed up construction and reduce waste. Rich Bloem of True North Homes has an extensive background in SIP construction.

Lumber: Our LEED home is constructed of wood. In addition to the SIP panels which have wood faces, we used wood floor joists and wood trusses to complete the building envelope. We sourced all of these materials locally and regionally as close to the site as possible. We determined that FSC certified wood was going to be very difficult and expensive to get for this particular project and thus decided to not pursue FSC certified wood based credits. We did look at the advantages and disadvantages of open web wood floor trusses versus TJI style pre-engineered floor trusses. There were representatives of each style of truss at the charrette which was incredibly valuable to the team. Because of the somewhat complex geometry of the floor framing systems we decided to go with the TJI style floor trusses on this particular project. Jed Nelson and Mark Paradowski, from Barry County Lumber Company where in attendance.

Plumbing: We looked at using Kohler brand fixtures for this particular project. We learned that there are many options to choose from but Kohler, and other major manufacturers, all do high-quality low flow fixtures that meet the highest standards in the LEED credits. We used the best performing, low flow fixtures for this project. We also supplemented the gas fired water heater with solar thermal system(s) mounted on the roof to preheat the water and save us energy. Ross Genzink, Genzink Plumbing was in attendance.

These are just a few of the things we learned in the integrated design process for this project.